|

Medical devices

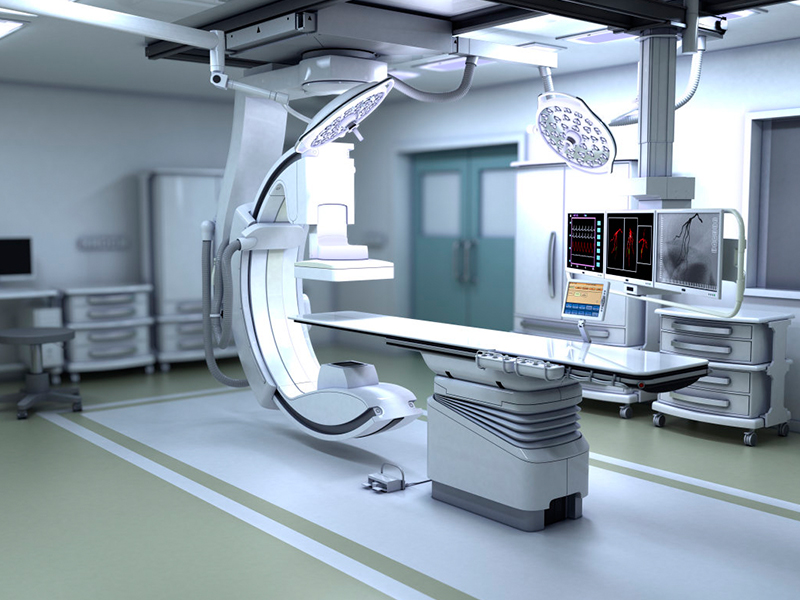

The medical device market, which uses only physical means to achieve performance without pharmacological or immunological means, is expanding worldwide and, because of its precise positioning, there is a growing demand for products with high speed, high precision, low noise, low vibration and maintenance-free equipment. The medical industry has two key requirements. Firstly, the level of hygiene: the environment and the equipment must always be clean, while frequent cleaning and detergents can lead to premature wear of mechanical components, affecting their life and operation. Secondly, the performance level of the machine must be accurate and consistent to ensure reliable results, the machine must be robust to withstand heavy loads and must be compact to allow multiple components to be mounted in an enclosed space. With the development of high-speed, high-precision diagnostic instruments, high demands are placed on the bearings and linear products used for high speed, high precision, high rigidity, low vibration, low noise and maintenance-free operation. In the face of such challenges, new equipment needs to be able to provide faster, safer and more reliable diagnosis and medical treatment, while improving the comfort of patients and operators. In diagnostic imaging systems, not only safety but also low vibration and noise are required for instruments that move with a person on board. Our new products achieve low vibration and noise compared to previous products and, by increasing the load capacity, contribute to the miniaturisation and lightness of the device. Specially designed bearings to meet the needs of medical devices We are able to specialise in the design and production of bearings used in medical devices, and special new material coating technology and lubrication solutions are available to support the medical industry with technological innovations for medical devices. |